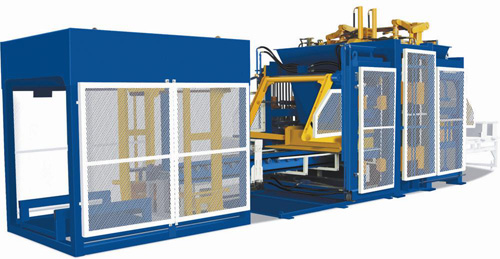

Block Molding Machine

2012-02-21 07:39:00 | 阅读(656)

General information:

Characteristics :

With long-distance control function.

Rigidity synchronizer in the way of crutched arms, which avoid the green blocks damaged when mould frame lifting

Integrated vibrating bin and vibrating table, improve reliability of vibrating table.

Advance vibrating technology. Feeding and forming by different vibrating mode assures high quality of feeding and forming.

Main Products:

Standard block (390×190×190mm 1,200pcs./hour)

Standard block (400×200×200mm 1,000pcs./hour)

Standard brick (240×115×53mm 7,200pcs./ hour)

Porous brick (240×115×90mm 3,840pcs./hour)

Mosaic brick (250×250×(50~80)mm 1,920pcs./ hour)

Curb (500×300×120mm 480pcs./hour)

With long-distance control function.

Rigidity synchronizer in the way of crutched arms, which avoid the green blocks damaged when mould frame lifting

Integrated vibrating bin and vibrating table, improve reliability of vibrating table.

Advance vibrating technology. Feeding and forming by different vibrating mode assures high quality of feeding and forming.

Main Products:

Standard block (390×190×190mm 1,200pcs./hour)

Standard block (400×200×200mm 1,000pcs./hour)

Standard brick (240×115×53mm 7,200pcs./ hour)

Porous brick (240×115×90mm 3,840pcs./hour)

Mosaic brick (250×250×(50~80)mm 1,920pcs./ hour)

Curb (500×300×120mm 480pcs./hour)

Applications:

This machine is suitable for customers with small or medium amount of investment. Meanwhile, the biggest difference of Model T5-15 Block Production Line is that it is developed independently by CNBM, who boasts a batch of self-owned core technology. The production line is magnanimous in layout and smooth in its technological line. It is proved to be perfect configuration and reliable performance.

The equipment applies to the production of high tensile and high quality of conventional concrete block, fly ash block and waste residue block. It is among the most reliable and most advanced models of CNBM. The overall technical level leads the nation. With modular design, the equipment takes the users’ desire of the participation in design into account and leaves adequate room to meet the demands of users. It offers users with individualized products based on generality and reliability. The production line consists of batching and mixing system, forming system and block stacker.

The equipment applies to the production of high tensile and high quality of conventional concrete block, fly ash block and waste residue block. It is among the most reliable and most advanced models of CNBM. The overall technical level leads the nation. With modular design, the equipment takes the users’ desire of the participation in design into account and leaves adequate room to meet the demands of users. It offers users with individualized products based on generality and reliability. The production line consists of batching and mixing system, forming system and block stacker.

Technical Data:

Dimension:6600×1990×3000mm

Rating pressure:21MPa

Vibration: Table vibration

Vibration frequency:2800—4500r/min.

Pallet size: 1100×560mm

Cycle time: 15—25 sec.

Power: 34.9kW

Weight: 11800kg

Daily Capacity(8 hours):

Solid bricks(240×115×53mm) 61,440 Pcs.

Porous bricks (240×115×90mm)30,720 Pcs.

Blocks (390×190×190mm) 9,600 Pcs.

Rating pressure:21MPa

Vibration: Table vibration

Vibration frequency:2800—4500r/min.

Pallet size: 1100×560mm

Cycle time: 15—25 sec.

Power: 34.9kW

Weight: 11800kg

Daily Capacity(8 hours):

Solid bricks(240×115×53mm) 61,440 Pcs.

Porous bricks (240×115×90mm)30,720 Pcs.

Blocks (390×190×190mm) 9,600 Pcs.

- Pre:Building Hoist

- Next:PU Sandwich Panel Line